Are you in the right country?

Now you are at Romania.

Any change of position while the purchase will cause the items to be removed from the shopping cart.

Click here to see the list of available countries.

- 618 gr. (172,5 mm, 34-50, 2 bearings assembled)

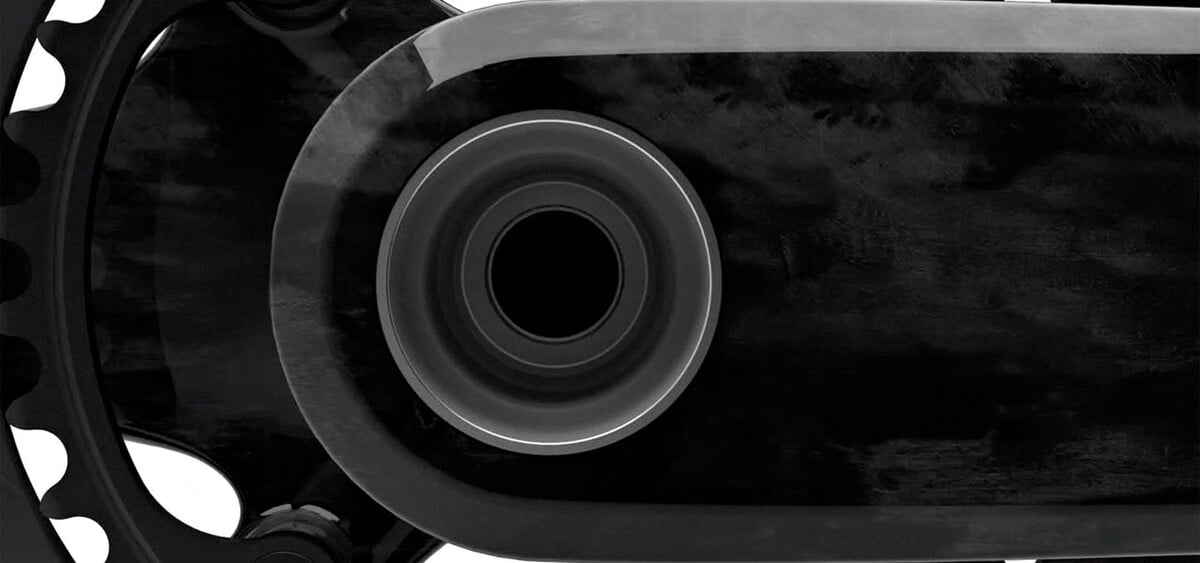

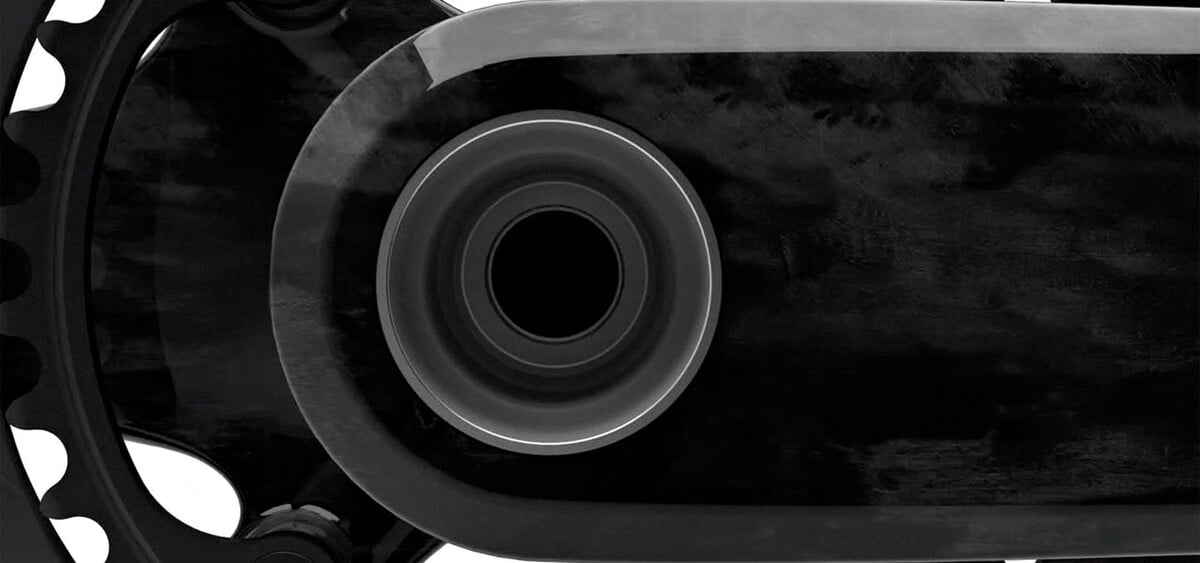

CULT - CERAMIC ULTIMATE LEVEL TECHNOLOGY

Thanks to their properties, produced to specific Campagnolo design, CULT bearings offer extremely low friction, enabling maximum performance and energy savings when pedaling.

MPS™ MICRO PRECISION SHIFTING SYSTEM

The evolved design of the up-shift and down-shift zones and of the teeth profile enables fast, precise shifting in any conditions

ULTRA-TORQUE™

Lightness, stiffness, and simplified assembly: ULTRA-TORQUE™.

X.P.S.S.™ EXTREME PERFORMANCE SHIFTING SYSTEM

X.P.S.S.™ technology is the embodiment of a project conceived with a very specific objective: to give Campagnolo 12-speed groupsets the best possible derailing performance.

The iconic CULT - ceramic bearings for Campagnolo - are only mounted on the best cranksets and are revolutionary compared to other bearings on the market. Thanks to their properties, produced to specific Campagnolo design, CULT bearings offer extremely low friction, enabling maximum performance and energy savings when pedaling. The top-quality ceramic balls with high-precision roundness and resistance turn inside polymer cages on stainless steel races that are extremely resistant to wear and tear. These cages are designed with tolerances accurate to the micron, which maximizes their efficiency and durability. CULT bearings do not deform or corrode, ensuring long-term constant performance and product quality. Their maintenance requires only periodic cleaning and light lubrication with synthetic oil. CULT bearings have a 40% lower friction coefficient than standard sealed bearings and they roll for 5 and a half times longer in tests. CULT ceramic bearings are available for the best-known Campagnolo racing bike wheels: Bora Ultra WTO, Ghibli and Hyperon Ultra.

Campagnolo constantly strives to achieve maximum performance from all its ranges of groupsets, from Super Record Wireless to Ekar™. The Micro Precision Shifting™ (M.P.S.™) System fully reflects this company philosophy: absolute precision, speed and a reduction of the distance covered by the chain when moving from one chainring to another. Mechanical work on the outer chainring is proof of the obsessive attention to detail and the perseverance of our Campy Tech Lab™ designers, who aim for maximum performance from all of Campagnolo’s products. The result is surprising and changing chainrings, even under load, is now no longer a problem! The evolved design of the up-shift and down-shift zones and of the teeth profile enables fast, precise shifting in any conditions.

Lightness, stiffness, and simplified assembly: ULTRA-TORQUE™. Campagnolo® has permanently conjoined the semi-axles of the bottom bracket to the respective crankset arms. This redesign has made it possible to considerably reduce the lateral dimensions at the axle level and prevent annoying contact with the ankles when turning the pedals. Assembly couldn’t be simpler: a single oversize bolt is enough to integrate the two semi-axles. This breakthrough was achieved thanks to an ingenious mechanical system derived from many years’ experience in the coupling and rotation axle sector: the Hirth joint. This is basically a joint with self-centering, self-aligning frontal teeth positioned in the middle of the bottom-bracket axle where the ends of the semi-axles, integrated with the crankset arms, come into contact. Where torque transmission is concerned, this system is equally as effective as a single-piece axle, which therefore guarantees unrivalled power transmission.

X.P.S.S.™ technology is the embodiment of a project conceived with a very specific objective: to give Campagnolo 12-speed groupsets the best possible derailing performance. The ascent and descent zones on the chainrings have been designed down to the smallest detail, using mathematical simulation programs that reproduce the potential movements of the chain on the chainrings and draw their ideal angles. Repeated lab tests have achieved the final optimization of derailing speed and precision. The chainring teeth profile has also been revised in order to make their action even more effective and to ensure they are perfectly in tune with the 12-Speed chain and derailleur. All of these product evolutions enable an increase of 25% in derailing under load and of 20% in shifting fluidity. The secret behind this amazing result is the perfect combination and integration of all the drivetrain components: each of these is carefully designed to work and function perfectly with the others. The X.P.S.S. system is a Campagnolo technology used for the Record, Chorus and Centaur mechanical groupsets for racing bikes.